|

LLW卧式螺旋卸料过滤式离心机(液压型)

收藏

1.转鼓、螺旋等主要零件采用优质耐蚀不锈钢、钛合金等材料制造。 2.转鼓角度按工艺条件10°、20°可选。 3.专用过滤金属板网(厚度0.4~ 0.5mm)或梯形丝成型网(厚度4.5~ 5mm)可选。 4.变频控制,转鼓转速无级调速。 5.进料、分离、洗涤、脱水、推料连续完成,处理量大。 6.独立的润滑系统,润滑方式简单可靠,冷却效果好。 7.安全保护:可配置转速检测,过振动保护,电机过载过热保护。8.对于大粘度物料,可选用液压差速器,工作稳定可靠。 1. Rotary drum, screw and other main parts are made of high-quality corrosion-resistant stainless steel, titanium alloy and other materials. 2. The drum Angle according to the process conditions of 10 ° 20 °, optional. 3. Special filter metal plate mesh (thickness 0.4~ 0.5mm) or trapezoidal wire shaped mesh (thickness 4.5~ 5mm) is optional. 4. Frequency conversion control, stepless speed regulation of drum speed. 5. Feeding, separation, washing, dehydration and pushing are completed continuously with large processing capacity. 6. Independent lubrication system, simple and reliable lubrication, good cooling effect. 7. Safety protection: speed detection, over-vibration protection and motor overload and overheating protection can be configured.8. For materials with high viscosity, hydraulic differential can be selected for stable and reliable operation.

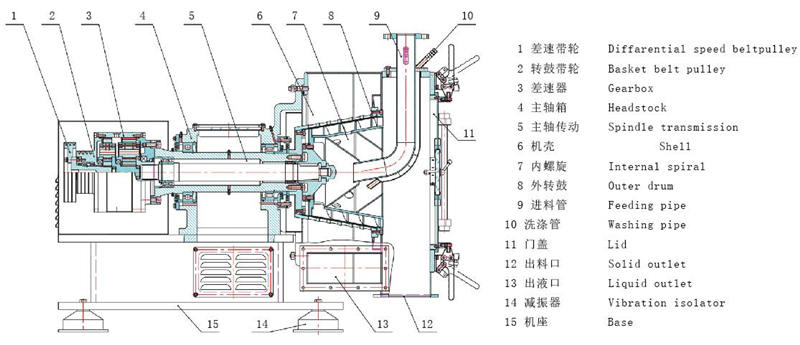

LLW型卧式螺旋卸料过滤式离心机是种能耗低、性能稳定、分离效果好的机型。分离过程中的进料、脱水、洗涤、卸料等工序连续完成,生产效率和自动化程度高,是种先进的固液分离设备。 悬浮液从进料管进入螺旋内腔,并通过螺旋小头接近锥端底部的喷料口进入转鼓,在离心力场的作用下,料浆中的液相通过铺设在转壁上的筛网被过滤出去,固相颗粒则被截留在转鼓内;同时,转鼓内的固相颗粒在离心力和螺旋与转鼓之间的相对差速作用下,从转鼓小端向转鼓大端运动,在此运动过程中,由于回转直径的加大,离心力得到快速递增,固相从初始进入时的较高含湿量到排出转鼓时达到最低含湿量固相,从而实现固液相自动、连续的分离。 离心机内置洗涤管,可在滤饼过滤的同时对滤饼进行洗涤。由于是薄层滤饼洗涤,洗涤效果好,洗涤液消耗低。在转鼓背面可设计蒸汽管,对转鼓背面结晶的物料进行高温洗涤。 螺旋差速器有摆线差速器,行星差速器和液压差速器三种配置,满足不同物料的分离。 LLW horizontal spiral discharge filtration centrifuge is a type with low energy consumption, stable performance and good separation effect.It is an advanced solid-liquid separation equipment with high production efficiency and automation. The suspension enters the spiral inner chamber from the feeding tube and enters the drum through the nozzle near the bottom of the cone end. Under the action of the centrifugal force field, the liquid phase in the slurry is filtered out through the screen laid on the rotating wall, and the solid phase particles are trapped in the drum.At the same time, the drum of solid phased particles in centrifugal force and the screw and the relative differential between the drum, the drum to drum heel movement, in the process of the movement, because of the turning diameter increased, increasing centrifugal force to get fast, solid phase from the initial into the higher moisture content to discharge drum reached the minimum moisture content solid phase, so as to realize the separation of solid and liquid automatic, continuous. The centrifuge has built-in washing tube, which can wash the filter cake while filtering it.Since it is a thin layer filter cake washing, the washing effect is good and the detergent consumption is low.The steam pipe can be designed on the back of the drum, and the crystallized material on the back of the drum can be washed at high temperature.Screw differential has three kinds of configuration, cycloid differential, planetary differential and hydraulic differential, which can meet the separation of different materials.

LLW卧式螺旋卸料过滤式离心机广泛应用于化工、食品、盐、采矿、制药等行业。 因其分离原理和结构特性,其对物料的针对性也较强,主要适用于具有较大颗粒度、对颗粒破碎没有严格要求的物料。在选型时应进行物料分析和相应的试验,以确定其适用和分离性能。 LLW horizontal spiral discharge filtration centrifuge is widely used in chemical, food, salt, mining, pharmaceutical and other industries. Due to its separation principle and structural characteristics, it is also more targeted to the material, mainly suitable for materials with larger particle size, no strict requirements for particle breakage.Material analysis and corresponding tests should be carried out to determine its applicability and separation performance.

|