|

PGZ平板式刮刀下部卸料自动离心机

收藏

PGZ系列离心机是一种含有高科技含呈的离心分离机械,具有多种配置可选择,可实现全自动程序控制,具有无菌卫生、密闭防爆、多重安全保护、多种配置选择等特点,广泛应用于制药、精细化工、食品等行业。 PGZ series centrifuge is a kind of centrifugal separation machine with high technology. It is widely used in pharmaceutical, fine chemical, food and other industries. It is widely used in pharmaceutical, fine chemical, food and other industries.

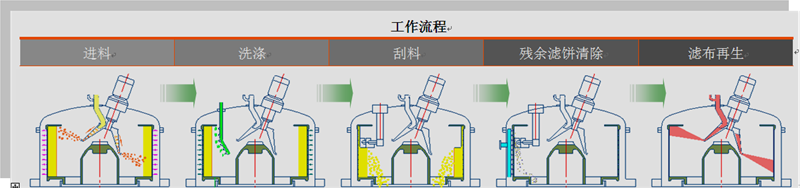

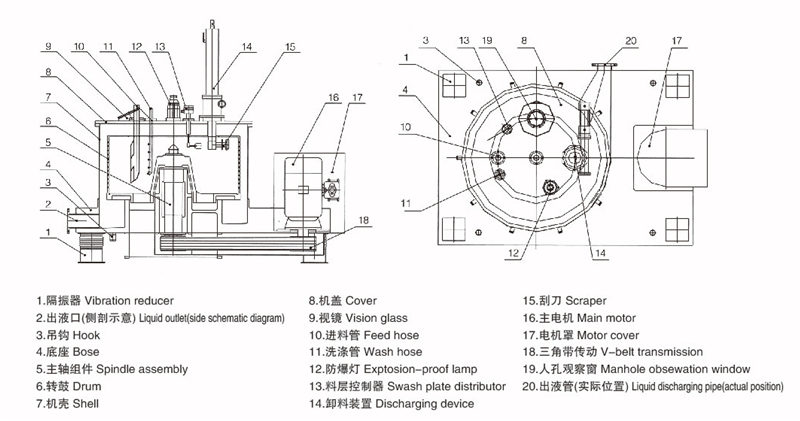

刮刀下部卸料离心机为立式全自动过滤离心机。电机通过皮带驱动转鼓高速旋转,待分离的物料在预先编制的程序控制下,通过进料系统进入高速旋转的离心机转鼓内。 在离心力场的作用下,物料通过过滤介质(滤布/滤网)的过滤,液相经出液管排出机外,固相则被截留在转鼓内。物料检测装置实时检测物料充填位置,当转鼓内滤饼达到机器规定的装料量时,停止进料。然后对滤饼进行洗涤、甩干。滤饼达到脱液要求后,离心机降低到刮料速度,刮刀装置在液(气)动控制下将滤饼刮下,并经离心机下部的出料口排出。 The bottom discharge centrifuge of scraper is vertical automatic filtration centrifuge.The motor drives the drum through the belt to rotate at a high speed. The material to be separated is controlled by a pre-programmed program and enters the centrifuge drum at a high speed through the feeding system. Under the action of centrifugal force field, the material passes through the filtration medium (filter cloth/filter net), the liquid phase is discharged through the outlet pipe, and the solid phase is trapped in the drum.The material detection device detects the filling position of the material in real time. When the filter cake inside the drum reaches the loading quantity specified by the machine, the feeding is stopped.Then wash and dry the filter cake.After the filter cake meets the requirements of liquid removal, the centrifuge will reduce to the speed of scraping. The scraper device will scrape the filter cake under the control of liquid (gas) and discharge it through the discharge port at the bottom of the centrifuge.

主要用于含有固相颗粒的悬浮液的固液分离,也可以用于纤维状物料的固液分离。特别是对粘度高、粒度细、有毒、易燃易爆物料的分离。 如抗生素、维生素、医药中间体等医药产品,食盐、味精、食品添加剂、淀粉、制糖、化学调味剂等食品,硫铵、石膏、芒硝、硫酸铜、氯化钾、硼砂、染料、颜料、树脂、农药药剂等化工原料,以及矿山环保等行业中的固液分离工作。离心机自动化程度高,处理量大,可实现远程控制。 It is mainly used for solid-liquid separation of suspension containing solid phase particles, and can also be used for solid-liquid separation of fibrous materials.Especially for high viscosity, fine particle size, toxic, flammable and explosive material separation. Pharmaceutical products such as antibiotics, vitamins, pharmaceutical intermediates, salt, MSG, food additives, starch, sugar, chemical seasoning, such as food, sulfur, gypsum, ammonium glauber's salt, copper sulfate, potassium chloride, borax, dyestuff, pigment, chemical raw materials, such as resin, pesticide drug and solid-liquid separation in industries such as mine environmental protection work.Centrifuge high degree of automation, large capacity, remote control can be achieved.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||